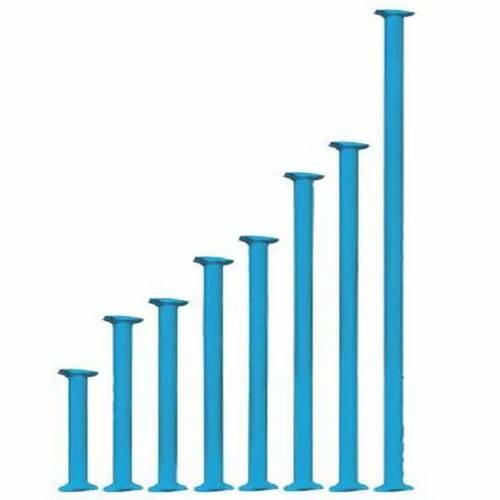

Cuplock Scaffolding System

Cuplock Scaffolding System Specification

- Features

- Good Quality

- Color

- Blue

- Product Type

- Cuplock Scaffolding System

- Material

- Mild Steel

- Components

- Other

- Length

- 6 Meter (m)

- Application

- Construction

- Size

- Standard

Cuplock Scaffolding System Trade Information

- Minimum Order Quantity

- 200 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5000 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Cuplock Scaffolding System

-

The system uses prefabricated steel components that can be assembled into various configurations, including mobile towers, modular scaffolding, and birdcage scaffolding.

-

Instead of bolts, the system relies on a unique locking node where forged ledger blades are inserted into a fixed lower cup on the standard.The upper cup is then hammered down to secure the ledger, providing a quick and rigid connection.

-

It can be used for both access scaffolding (work platforms) and shoring (load-bearing support), making it suitable for diverse applications like high-rise construction, industrial projects, bridge building, and more.

-

Constructed from high-tensile steel, the system has a high load-bearing capacity and is resistant to corrosion, often finished with a hot-dip galvanised coating for long-term use.

-

The main uprights of the system, with fixed lower cups welded at 0.5m intervals and a captive sliding upper cup.

-

Connect adjacent standards, providing support for the scaffold platform and transferring loads.They are inserted into the cups on the standards.

-

Provide lateral stability and prevent sway.They connect to the standards and ledgers.

-

This includes base jacks for leveling, hop-up brackets for widening platforms, transoms for intermediate support, and toe boards and guardrails for safety.

Superior Construction Support

Engineered from premium mild steel, the Cuplock Scaffolding System delivers exceptional strength and stability on construction sites. Its standard sizing and 6-meter length simplify planning and installation, accommodating diverse building elevations and layouts with ease.

Efficient Assembly and User-Friendly Design

Featuring a user-centric cuplock mechanism, this system enables rapid assembly and disassembly. The blue finish offers corrosion-resistance, ensuring the scaffolding remains dependable for prolonged use even in demanding environments.

FAQs of Cuplock Scaffolding System:

Q: How is the Cuplock Scaffolding System installed on a construction site?

A: The Cuplock Scaffolding System utilizes a locking mechanism that allows components to connect without tools. Workers simply position the horizontal ledger into the cuplock joints and secure them, enabling quick and safe assembly.Q: What materials are used in the construction of this scaffolding system?

A: This scaffolding system is primarily made from mild steel, chosen for its high load-bearing capacity and durability. The material also provides resilience against wear, making it suitable for repeated assembly and disassembly.Q: When is the Cuplock Scaffolding System most beneficial during construction?

A: It is especially beneficial during phases requiring elevated work platforms, such as masonry, plastering, or structural repairs, thanks to its stability, ease of use, and composite design.Q: Where is this scaffolding system manufactured and supplied?

A: The Cuplock Scaffolding System is manufactured and supplied in India, offering convenient access for local construction companies and ensuring compliance with regional standards.Q: What is the process for maintaining this scaffolding system?

A: To maintain the Cuplock Scaffolding System, regularly inspect each component for signs of corrosion, especially despite its blue protective coating. Clean parts before storage and ensure connections remain free from debris for optimal performance.Q: How does using this system benefit construction projects?

A: Using the Cuplock Scaffolding System enhances project safety and efficiency. Its modular design accelerates the setup process, reduces labor costs, and provides a stable working platform, which collectively improves productivity and minimizes risks.

Price 62 INR/ Kilograms

- Minimum Order Quantity

- 200 Kilograms

- Supply Ability

- 5000 Kilograms Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scaffolding Accessories Category

Cuplock Ledger Thumbs

Price 62 INR / Kilograms

Minimum Order Quantity : 100 Cubic Feet

Material : Other , Mild Steel

Application : Construction

Features : Good Quality

Mild Steel Scaffolding Steel Chali

Price 65 INR / Kilograms

Minimum Order Quantity : 200 Kilograms

Material : Other , Mild Steel

Application : Construction

Features : Rust proof

Surface Treatment : Other, Color Galvanized

Mild Steel Scaffolding Joint Pin

Price 60 INR / Kilograms

Minimum Order Quantity : 200 Kilograms

Material : Other , Mild Steel

Application : Construction

Features : Durable

Surface Treatment : Other, Galvanized

Scaffolding Ti Road

Price 65 INR / Meter

Minimum Order Quantity : 10

Material : Other , Iron

Application : Construction

Features : Rust proof

Surface Treatment : Powder Coating

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese